| Next Post - Previous Post List View

| |

| 6/12/2016 1:56:37 PM Bad Roofers... the gift that keeps on sucking. |

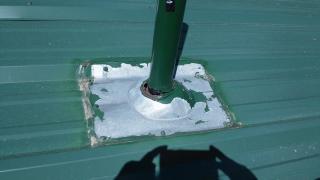

I would like to think that there are some good roofers out there, but all the ones I have experience with (both of them) did terrible jobs that resulted in leaking and damage, threatened to not finish if we didn't pay them the rest of the money, then never showed up again after taking the money. So there is lesson number one kids: NEVER pay the second half of contracted money until the work is 100% done and 100% right... even if that person is family of a friend of family. But in any case, half of the things that can be done completely wrong on a roof will be impossible to see until you have water flooding into your house, improperly installed vent pipes ripping off your roof, and foam water dams falling out from under the metal edge where they were supposed to be sealed in with fancy double-tape but weren't even put in the right places. Yeah. I will probably be trying to repair things done wrong for the entire life of this roof. (At least the first bad roofer in Georgia just didn't bother sealing the flashing the way it should have been for tropical storms and never put flashing around the porch edge.) So, up on the list for today... rigging supports for the improperly installed vent pipes. For a little history: the insurance required that the roofers extend the vent pipes on our roof. So the first thing the roofer did was trying to yank them up a couple feet higher from the roof, which would dislodge them from where they should be in the house and let sewer gas flow into the walls and water run into the walls from the vent pipes, yeah, isn't that a great idea? And how do I know he did this? Because one of the vent pipes had to be re-routed and I was in the process of pvc gluing the pipe in place when he yanked it two foot up! When that would not work, instead of just getting a coupling to extend the pipe, they cut off the pipes just below the surface of the roof, then put on a thin coupling without gluing it with pvc glue and then just threw some flashing and caulk around it.  So the first time some snow slid on the roof, it ripped the pipe right off, bent the flashing and let water into the house. So the first time some snow slid on the roof, it ripped the pipe right off, bent the flashing and let water into the house.I have been repairing each one as it happened, making them stronger by gluing them properly, but because of the thin coupling they used and never got properly glued, two of them ripped off even after being glued as best as I could after the fact. Worse, because the pipe wasn't secured in the hole in the roof like it was before (nice and tight), even if the pipe didn't rip off, it cracked the caulking around the pipe and still let water in. So after repairing them for the last time by inserting a slightly smaller pipe down inside well past both sides of the coupling, I decided that it was time to figure out some kind of support to keep them from shifting at all. They make industrial strength brackets for this purpose. The benefits to this bracket support work in two ways. It helps prevent the pipe from shifting when sliding snow hits it, but it also helps cut the snow as it slides down the roof before it gets to the pipe, and makes the snow easily slide along the sides of the pipe instead of hitting it broad-side. However, for $60 to $80 each, I could not justify that expense for something meant to keep a chimney on through an avalanche. So I got some aluminum bar stock, pipe clamps, and some special "Gutter and Flashing" caulk. I cut the bar stock in half to get 2ft sections, drilled holes on the ends, and bent the ends around 45 degrees, then headed up onto the roof. Always remember good grippy shoes, especially on a slick metal roof. I screwed the upper piece to the pipe with a decking screw so that the pipe clamp would not be able to slide off the bracket or get out of place. Then tightened the clamp. Then I drilled a small pilot hole into the roof metal, caulked all around the roofing screw under the bracket end and tightened the screw to the roof. The last process was to caulk all around the vent pipe base again. A small piece of plastic helped get fairly smooth and fully sealed coverage. Once it is fully dry and cured, I can paint all the parts with some spray paint that matches the roof (almost). But in the mean time, at least it is secure and sealed, even if it doesn't look great. And on to the next pipe.  Of course, the one pipe the roofers didn't destroy (and I put on an extension myself ABOVE the roof line with a good coupling and pvc glue), never has had a single problem, but a little extra support could not hurt, so I gave it a bracket as well. Of course, the one pipe the roofers didn't destroy (and I put on an extension myself ABOVE the roof line with a good coupling and pvc glue), never has had a single problem, but a little extra support could not hurt, so I gave it a bracket as well.After that, I spent another hour or so gluing in that foam water dam at the bottom edge of the roof, so maybe... just maybe... the roof is at least not going to randomly leak for a while. Next roof related project will be to repair the water damage that was caused by them not sealing around the skylights properly. Always something.

| |

Next Post - Previous Post List View | |

Add Your Comment...

I guess I can also say that it is a miracle as to how you get it all done and not be hurt. You do some dangerous things like your being on the roof. Do you by any chance take the phone up there with you? Do you by any chance keep the phone close by every time you are doing any project?

Roof project looks great!