| Next Post - Previous Post List View

| |

| 9/18/2016 12:33:08 PM Not Shocking but a Little Bloody. |

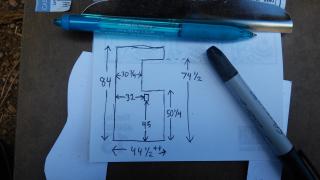

While the weather was mostly agreeable, I got the workshop interior insulated and the foam-board up for the ceiling.

None of which is fun, but I was very careful to wear a disposable long-sleeved shirt, hat, gloves, safety glasses, and a good quality breather to prevent self-damage from a whole lot of fiber-glass dust.  I was less careful about some spray foam and ended up with it stuck in my hair and rolling down the sliding glass door like a wall-slap toy from the 80's, leaving tracks of impossibly sticky foam behind. Not a smart idea. I was able to remove the foam from the glass right away with a bunch of acetone (fingernail polish remover), but for my hair, I had to wait for it to fully cure and then scrape and pull my hair out of it. I was less careful about some spray foam and ended up with it stuck in my hair and rolling down the sliding glass door like a wall-slap toy from the 80's, leaving tracks of impossibly sticky foam behind. Not a smart idea. I was able to remove the foam from the glass right away with a bunch of acetone (fingernail polish remover), but for my hair, I had to wait for it to fully cure and then scrape and pull my hair out of it.After the foam disaster, I got smart and used some cardboard supports and drip catchers to get more foam where it needed to go. Then I got the OSB walls up. And despite taking a few days to complete, it was mostly pretty easy. The super special cuts for the ends were annoying though, and I ran out of screws the right size and type, so many of the panels are up with just the minimum and will need more screws later. However, after already scraping and denting the foam-board ceiling several times, I decided that I had better get OSB up there as well before I seal and paint everything. Of course, I didn't have the right size screws, so it had to wait and will hopefully get done this coming week. While the walls went up with relative ease, I was surprised to find that the electrical, that I thought would be a complete breeze, was MUCH harder than I expected. Thick 12 gauge wire made for difficult bending back into boxes, and despite using all the special tactics for proper wire installation... like zig-zagging the wires so they would go in easily... nothing was easy about it. Worse yet, was the junction at the far end of the workshop where many wires needed nutted together and after a couple attempts, and a fingertip sliced neatly open with a razor cutter, I realized that there was simply no possible way those wires would fold and fit into the double-box... let alone with a bunch of big wire-nuts all over. Impressively enough, and not counting some bruises and major soreness, this is my very first real injury on this project. Unfortunately the location made it very hard to band-aid together and once it scabbed a little I have been holding it closed with super-glue and wishful thinking. So work screeched to a halt on Friday, and Saturday was spent in town getting screws and special electrical stuff. I feared that I would need to put in two four-gang boxes to fit all those wires and nuts, but with some special push-connectors and an extra-deep three-gang box, everything fit without problems. (Those push-connectors are really nice by the way and I went back to several other spots and replaced nuts with them.) And now the happy report of electricity! Plugs powering, switches switching, and junctions.... er.... junctioning? If I were running at full speed, I would now be cutting the OSB for the ceiling and figuring some kind of complex system of braces to get it up there... but I am definitely slowing down and not running at top speed. Of course, I got the wall primer and floor paint on Saturday, too, so getting the ceiling OSB done is pretty high on the list of "Get-er-done". Ummmmm..... tomorrow. | |

|

POST LINKS FORWARD TO: 9/29/2016 9:29:09 AM - Two months later... and the shed is OFFICIALLY DONE. | |

|

POST LINKS BACK TO: 9/10/2016 8:25:46 AM - Just in Time! | |

Next Post - Previous Post List View | |

Add Your Comment...

All the other things you have done are as always amazing. I would never have undertaken the electrical part of any project. I don't even plug something into the wall if I can get someone else to do it.

(I was electrocuted once, being barefoot on a concrete garage floor and grabbed a huge deep freezer handle before my dad has gotten it grounded. The shock threw me from the front of the garage to the rear and I couldn't get up) Any way I have a great respect for the work you do.