| Next Post - Previous Post List View

| |

| 4/20/2015 2:20:56 PM Three Plumbing Projects |

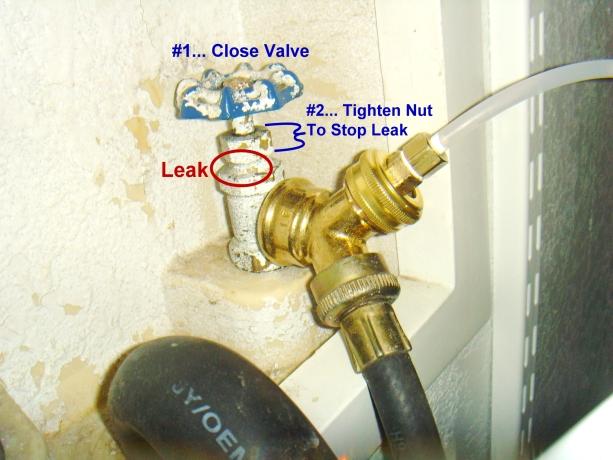

In the past, plumbing projects were usually limited to fixing the guts of a toilet or the leaky drain of a sink. Things involving easily accessed PVC or threaded fittings. As soon as it got to metal pipes, the home-owner either had to learn to "sweat" pipes with solder and a torch, or call a plumber. Now, with push-fittings, home-owners everywhere can take back the repairs to copper pipes, and maybe get a little creative, too. Of course, one thing to note is that you should make sure your pipes have enough movement to get the valve in between and push them together, or push-fit may not work for your project. Project #1... Replacing a Water Heater Fill Hose and Shut-off Valve Our fist pipe project is the result of my putting a saddle-T valve on the connection to the water heater. Not a great idea, I knew it at the time, but I needed to run a 1/4 inch water line to our RO water filter for our saltwater tank. I didn't know what else to do, though a better method is project number three on this page. The trouble with saddle-T valves is that they are terribly prone to leaking, especially if you have to turn them off and on more than once. Another problem is that they have a steel needle and when used with copper piping it encourages corrosion in the surrounding areas. Not only had the T valve started leaking, but the shutoff for the cold line to the water heater was also running a slow drip.   So early the morning of Saturday the 11th, hubby and I filled a bucket of water for hand washing before shutting off the water main to the house, then took off the line to the water heater and made attempts at removing the valve stem to the shut-off. The paint made it all but impossible to take the valve apart to get to the rubber washer inside, and enough corrosion was visible on the stem that it would be better to replace instead of risk damaging the pipe inside the wall trying to take the valve apart. Luckily the pipe under all that paint was copper (as I am not sure if push-fittings work for iron). So early the morning of Saturday the 11th, hubby and I filled a bucket of water for hand washing before shutting off the water main to the house, then took off the line to the water heater and made attempts at removing the valve stem to the shut-off. The paint made it all but impossible to take the valve apart to get to the rubber washer inside, and enough corrosion was visible on the stem that it would be better to replace instead of risk damaging the pipe inside the wall trying to take the valve apart. Luckily the pipe under all that paint was copper (as I am not sure if push-fittings work for iron).With a quick cut from the saws-all, we had the valve off and took it with us to gather parts in town. After spending quite a while finding all the right parts to go from a push-fit valve to the hot water heater... with valve, adapter, etc, etc... we went over to the water heater hoses and found a push-fit valve that was connected to a flexible water heater line in one piece. Good lesson in looking for the simple solution first. With a little cleanup to remove all the paint on the pipe, including rough and fine sandpaper and a wipe-down, the pipe was ready for the push-fit side of the valve. Then it took exactly this amount of time: Carefully set the push-fit on the pipe... push on... have hubby double check that it was fully seated... thread the other end onto the hot water heater... tighten... tighten... snug with wrench... and... done. Water main turned back on... double check that there are no leaks both on and off. Fast... easy... no leaks. Project #2... Connecting hot water to a cold line with shut-off valves While gathering supplies for the hot water heater, we also got what we needed for an unusual project. The goal... To be able to run hot water through the spigot outside for cleaning of aquarium stuff and filling of my one-person jetted "hot tub".  Luckily all the pipes needed were exposed in the space behind our master bath and gas fireplace... discovered when we opened the wall to remodel the master bath. (More about that here.) Luckily all the pipes needed were exposed in the space behind our master bath and gas fireplace... discovered when we opened the wall to remodel the master bath. (More about that here.)To assure I was cutting into the right pipe, we ran hot water until the pipe was warm and I could mark the right one as "Hot". Then it was a matter of connecting to the cold pipe that runs to the spigot. I am visual, so pre-planning the assortment of options on a grid worked best for me. I decided to go with the straight connection so that I could attach the valves firmly to an existing stud to steady them when turning off and on. Shut off the main, open the sink and tub faucets to help drain, clean the pipes, mark, and ready to cut. (The inside lines are for cutting and the outside makes it easy to see if the fitting is pushed in as far as it needs to be.) I used pex for the pipe length since it is flexible and can make the curves I needed, however, elbows were needed for the cold water pipe to keep the curves mild. I used some of the cut out copper to connect the valves to the T so that the section is non-flexible and easier to attach to the 2x4. Push-fit saves the day again with no leaks and now I have the option to have hot, cold, or some of both outside by turning the valves here. An added benefit is that I can turn off both valves and open the spigot outside during the winter and have no risk of freezing at the spigot that way. Project #3... Installing a 1/4 inch line for a water filter from the washer valve  The third project we picked up parts for was to get a water line for our RO water filter system since the saddle-T valve would no longer be connected to our water heater fill hose. I first looked for any kind of connection that I could use at the 3/4 inch pipe at the water heater. A mind-boggling number of connections would have been needed though and I gave it up instantly when I found another way. The third project we picked up parts for was to get a water line for our RO water filter system since the saddle-T valve would no longer be connected to our water heater fill hose. I first looked for any kind of connection that I could use at the 3/4 inch pipe at the water heater. A mind-boggling number of connections would have been needed though and I gave it up instantly when I found another way.A splitter at the washing machine cold valve. The most difficult part of this project was propping up the shelf over my washer while dealing with the valve connections. Note that pipes shrink minutely when they get colder, so make sure your connections are wrench tightened (not just hand tight) or they may leak when you run cold water to the washing machine. Yes... I do know that the hard way now. ALSO, when you turn this style of valve off and on again for the first time in years, it is easy for the nut holding the stem down to loosen and cause a slight leak as well. It took me a little fiddling and then a google search to find out that usually all that needs done is to close the valve and tighten the upper nut. Quick fix that makes sense... unless you are me on a Tuesday I guess. I am glad it worked... since replacing this valve would have been a lot more annoying than the water heater valve. I also put an easy-to-get-to valve on the side of the cabinet that the RO unit feeds to. Plumbing Projects..... complete. At least until I think up something else to do or we have another leaky something. | |

|

POST LINKS BACK TO: 11/14/2014 3:49:58 PM - Guest Bathroom Pipe Drain | |

Next Post - Previous Post List View | |

Add Your Comment...

There are no problems or projects that you can't do, record and write about in step by step directions.

We are proud to call you friends, brag about your work and enjoy those benefits. We would still love you if you could do none of these things but you are truly extra special people.